Anthony Mannella is a Canadian businessman with a strong manufacturing acumen. He has more than 30 years of experience in manufacturing and has been successful operating in a number of capacities as a Production/Maintenance Manager, Quality Manager, Quality Engineer, Supplier Quality Engineer, Internal Auditor, Management Consultant, Business owner, mentor,trainer and motivator.

Most recently he has obtained certification as an ISO 9001, 13485 and IATF 16949, AS 9100 lead auditor Exemplar certified. He’s also ISO 26262 certified as a functional safety Engineer. Mr. Mannella has developed relationships with a Canadian 3rd party Certification body and is actively looking for new clients who can benefit from his expertise and connection to this Certification body.

Mr. Mannella is a Lean Six Sigma Black Belt and has provided a number of improvements and solutions in Quality for a number of Manufacturing clients. His knowledge and expertise has allowed him to develop and implement new process’s and strategies for his clients.

His 8-5-5-2 Kolbe profile makes him uniquely qualified as a strong fact finder, Strong manager/leader and Strong creative/critical thinker and solution provider.

Please feel free to reach out to find out more about his capabilities as well as his current opportunities for Certifications, Auditing, Training and Consulting.

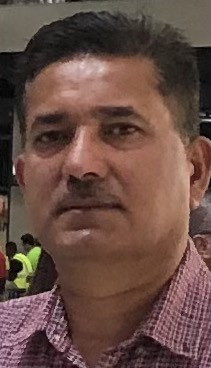

Mo Nassar is a demonstrated achiever with a solid background in collaboration with over 10 years experience in Quality systems, Lean Manufacturing and Scrap Reduction.

Mr. Nassar has helped many clients establish systems and processes for sustainable certification activities and ensured best practices were developed to achieve business targets.

Mr. Nassar has years of international experiences with proven capacity in problem-solving coupled with listening and communication skills. Having worked in North and South America makes him a good communicator and a strong team player.

John Buckland has over 40 years of experience in the design, developing and implementation of Quality and Productivity improvement programs using Lean manufacturing concepts and methods.

John lead External audit preparations (IATF, Q1, ISO,VDA, BIQS) and worked on building APQP for new programs. This includes the development and implementation of DFMEAs, PFMEAs, Control Plans, Data Collection systems and Standardized Work documentation.

John also worked in preparing PPAP packages and implemented Corrective Action projects including CS2 exit, Expedited Freight, Scrap Cost Reduction. As well as LEAN program implementation and training. And Attainment of FORD Q1 certification.

Atta has over 30 years of process, research/development experience in Heat-treatment technology, Nondestructive solutions, and Quality processes. Atta is well known for his “boots on the floor” approach with his many clients.

His unique approach to offering solutions to complex issues, design, and development work is valuable to many industries. Having process/product experience in multiple areas and applying them in project work provides value added service to many past and future clients. His expertise is proven in many major automotive companies. His approach to cost savings has resulted in millions of dollars in savings. Atta’s has as MSC in Metallurgy and Material science, as well as an MBA. These qualifications have been the building blocks for his skills in Metallurgical, Nondestructive, and quality disciplines. His working experience at General Motors, American Axle, and Managerial positions preceded him to acquire expertise in numerous metallurgical, nondestructive, and quality disciplines. He is certificated by American Society of Quality (ASQ): Six Sigma Black Belt. He is also Certified Quality Engineer, Certified Quality Auditor and Six Sigma green belt. He is also qualified through the American Society for Nondestructive Testing (ASNT) NDT Level III: Ultrasonic, Eddy Current, Magnetic Particle Inspection, Radiography. A certified Lead Auditor in IATF 16949 and certified to Shot peen Level II.

Mr. Bazizi is a highly qualified Quality specialist in a number of manufacturing verticals. He has performed over 1000 Audits (ISO 9001, 14001 & 45001) within Canada, USA, Mexico and North Africa in various Industries and services such as Engineering & Construction services, Oil & Gas, Mechanical, Chemical, Pulp and Paper, Electronics and Mining. He has also successfully implemented management Systems (Quality, Environment and health and Safety) in over 10 Companies (Engineering services and Manufacturing). Mr. Bazizi is also highly experienced in Engineering and Quality Management as he’s worked withing manufacturing companies in these capacities. Coupled with his many years of experience, he holds a BSc in Mechanical Engineering as well as a number of Lead auditor certifications in ISO 9001, 14001, 45001. Mr. Bazizi is stationed in Montreal Quebec and is positioned to properly serve and service our Quebec clients as he is fluent in both English and French.

Suhas Deshpande has over 20 years of success combining strong quality and business process improvement, and customer experience expertise to drive organizational effectiveness, value, and sustainability from the product development to the post-market customer service platforms. Proactive and solutions-driven strategist skilled in design and implementation of diverse business solutions focused on process and product quality, regulatory compliance, technical innovations, customer experience, and global optimization within strict timeline and cost-control goals.

Strong and highly engaged leader with proven track-record in managing multi-site global operations, building high performance & highly engaged multi-disciplinary teams, achieving cross-functional cohesiveness, and influencing commitment to improved business outcomes across all professional levels.

G.T is a driven professional with a proven track record in manufacturing. Offering experience in Lean manufacturing, program management, operational management, strategic planning and quality control. Effective in developing and working with diverse teams, implementing APQP processes and lean manufacturing principles.

Skilled in the development of shop floor core tools for selected manufacturing clients. Shop floor leadership in the improvement and overall knowledge of APQP and control plans. Provider of manufacturing gap analysis while improving process efficiency and cost avoidance.

Responsible for developing new supplier launch teams. Qualified to oversee the launch of suppliers for critical programs.

A Specialist in launching new programs and new plants.

A Skilled manager of Quality departments with overall responsibility of ensuring first time Quality to major automotive OEM’s.